-

airheaters@gmail.com -

View Mobile Number - Send SMS

- Send Email

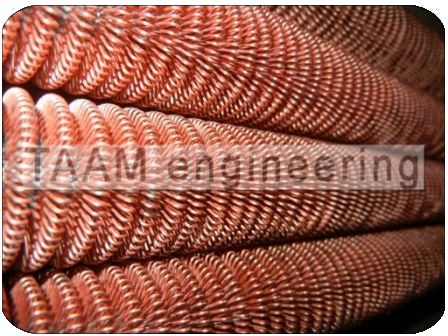

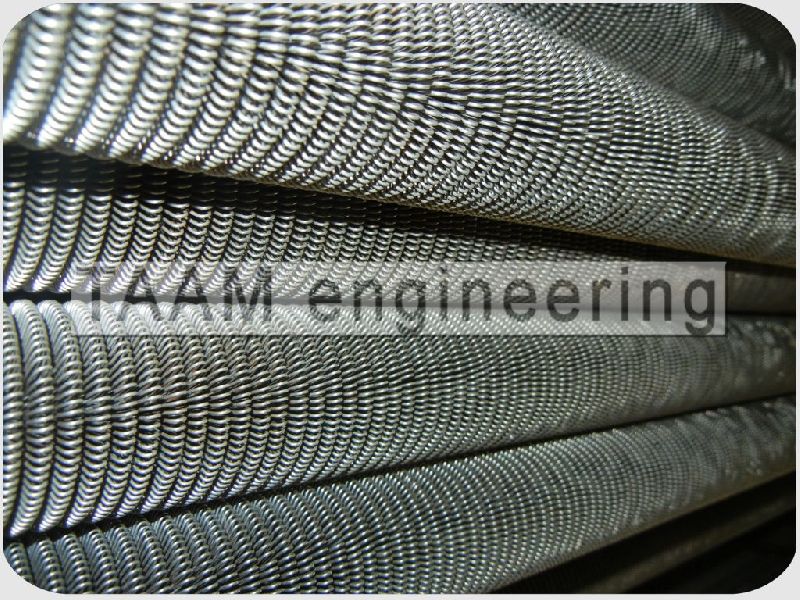

Wire Wound Fin Tubes

Leading Manufacturers, Exporters and Wholesaler of Copper Wire Wound Fin Tubes, Cupro Nickel Wire Wound Fin Tubes and Stainless Steel Wire Wound Fin Tubes from Nashik.

| Business Type | Manufacturer, Exporter, Supplier |

| Base Tube Material | Copper |

| Fin Wire Material | Copper |

| Tube OD | 3 mm to 120 mm |

| Fin Heights | 3 mm to 40 mm |

| Max. Length | No Limits as long it can be transported |

| Applications | Air Heaters, Air Coolers, Air Cooled Oil Coolers |

Preferred Buyer From

| Location | Anywhere in India |

Wire Wound Finned tubes are manufactured at TAAM engineering on specially developed high speed finning machines. Our machines are capable of wire wound finning tubes in lengths up to any length as long as it can be transported. We are manufacturers of wire wound finned tubes with base tubes of carbon steels, stainless steels, copper and copper alloys like cupro-nickels, admiralty brass, aluminum brass with copper wire fins, stainless steel wire fins and GI (galvanized iron) fins. The base tubes of our standard wire wound fin tubes range from 3 mm to 120 mm with fin heights ranging from 3 mm to 40 mm.

Wire Wound Fin tubing with higher fin heights can be made on demand.

Wire wound fin tubes are used for making compact heat exchangers like air coolers, air cooled oil coolers, air heaters, air to air heat exchangers. Wire wound fins are formed with wire formed into a loop and the loops of wire are wound helically over the tube with simultaneous root soldering of the fins to the outer surface of the tube. The air flowing over the fin tube go round about the 'legs' of the fin loop causing immense turbulence. The root soldering eliminates almost all air gaps between the fins and the tube. This coupled with high turbulence results in high air side heat transfer coefficient. The air side heat transfer coefficient is highest as compared to any other type of fin tube for identical areas and parameters.

Wire wound fin tubes for use in air cooled oil coolers are provided with internal fins selected from wide variations in configuration. We also manufacture double pipe wire wound fin tubes for use in refrigerated air dryers and heat exchangers for viscous and small streams.

| Business Type | Manufacturer, Exporter, Supplier |

| Base Tube Material | Cupro Nickel |

| Fin Wire Material | Cupro Nickel |

| Tube OD | 3 mm to 120 mm |

| Fin Heights | 3 mm to 40 mm |

| Max. Length | No Limits as long it can be transported |

| Applications | Air Heaters, Air Coolers, Air Cooled Oil Coolers |

Preferred Buyer From

| Location | Anywhere in India |

Wire Wound Finned tubes are manufactured at TAAM engineering on specially developed high speed finning machines. Our machines are capable of wire wound finning tubes in lengths up to any length as long as it can be transported. We are manufacturers of wire wound finned tubes with base tubes of carbon steels, stainless steels, copper and copper alloys like cupro-nickels, admiralty brass, aluminum brass with copper wire fins, stainless steel wire fins and GI (galvanized iron) fins. The base tubes of our standard wire wound fin tubes range from 3 mm to 120 mm with fin heights ranging from 3 mm to 40 mm.

Wire Wound Fin tubing with higher fin heights can be made on demand.

Wire wound fin tubes are used for making compact heat exchangers like air coolers, air cooled oil coolers, air heaters, air to air heat exchangers. Wire wound fins are formed with wire formed into a loop and the loops of wire are wound helically over the tube with simultaneous root soldering of the fins to the outer surface of the tube. The air flowing over the fin tube go round about the 'legs' of the fin loop causing immense turbulence. The root soldering eliminates almost all air gaps between the fins and the tube. This coupled with high turbulence results in high air side heat transfer coefficient. The air side heat transfer coefficient is highest as compared to any other type of fin tube for identical areas and parameters.

Wire wound fin tubes for use in air cooled oil coolers are provided with internal fins selected from wide variations in configuration. We also manufacture double pipe wire wound fin tubes for use in refrigerated air dryers and heat exchangers for viscous and small streams.

| Business Type | Manufacturer, Exporter, Supplier |

| Base Tube Material | Stainless Steel |

| Fin Wire Material | Stainless Steel |

| Tube OD | 3 mm to 120 mm |

| Fin Heights | 3 mm to 40 mm |

| Max. Length | No Limits as long it can be transported |

| Applications | Air Heaters, Air Coolers, Air Cooled Oil Coolers |

Preferred Buyer From

| Location | Anywhere in India |

Wire Wound Finned tubes are manufactured at TAAM engineering on specially developed high speed finning machines. Our machines are capable of wire wound finning tubes in lengths up to any length as long as it can be transported. We are manufacturers of wire wound finned tubes with base tubes of carbon steels, stainless steels, copper and copper alloys like cupro-nickels, admiralty brass, aluminum brass with copper wire fins, stainless steel wire fins and GI (galvanized iron) fins. The base tubes of our standard wire wound fin tubes range from 3 mm to 120 mm with fin heights ranging from 3 mm to 40 mm.

Wire Wound Fin tubing with higher fin heights can be made on demand.

Wire wound fin tubes are used for making compact heat exchangers like air coolers, air cooled oil coolers, air heaters, air to air heat exchangers. Wire wound fins are formed with wire formed into a loop and the loops of wire are wound helically over the tube with simultaneous root soldering of the fins to the outer surface of the tube. The air flowing over the fin tube go round about the 'legs' of the fin loop causing immense turbulence. The root soldering eliminates almost all air gaps between the fins and the tube. This coupled with high turbulence results in high air side heat transfer coefficient. The air side heat transfer coefficient is highest as compared to any other type of fin tube for identical areas and parameters.

Wire wound fin tubes for use in air cooled oil coolers are provided with internal fins selected from wide variations in configuration. We also manufacture double pipe wire wound fin tubes for use in refrigerated air dryers and heat exchangers for viscous and small streams.